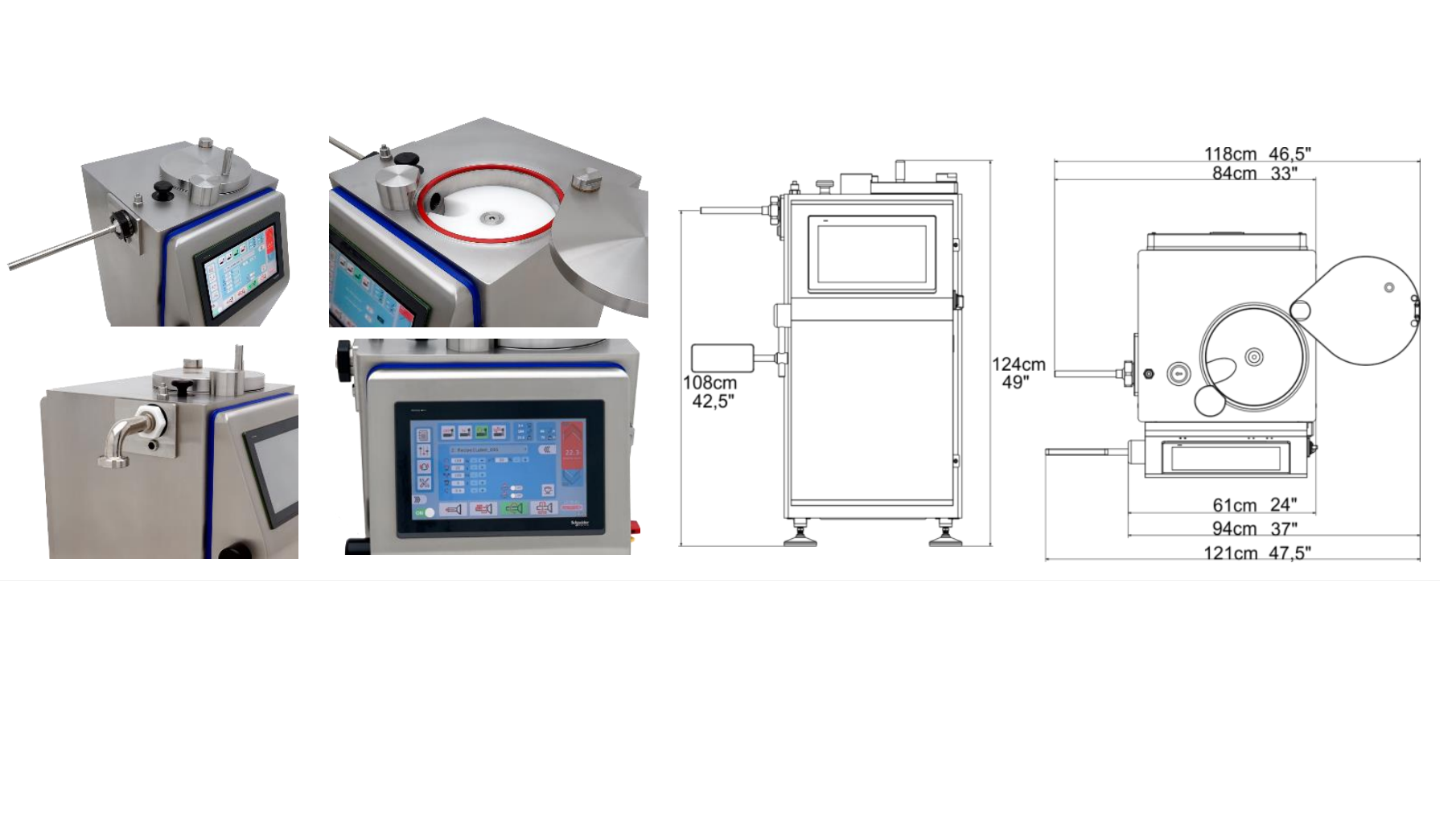

Šifra izdelka: 4144

Cena z DDV:Avtomatska hidravlična polnilka FPT30

Proizvajalec TALSA (Španija)

Volumen 30 lit.

Integrirana porcioner in frkalica

Digitalna nadzorna plošča

Zelo enostavna uporaba

Teža 220 kg

Napetost 400V

NEW 30L PISTON FILLER WITH DIGITAL PORTIONING AND NOZZLE TWISTING

The new Talsa FPT30 digital automatic filler / dosing / nozzle twister has been designed

for medium size processors who need to fill and precisely portion a wide variety of food

products with a single machine. 30 litre barrel capacity allows the production of medium or

small batches without waste and quick product changeover.

AT WORK: • Various assistance systems help the user to find the most efficient way to the

desired product. • Intuitive calibrating system to produce exact weight portions in relation to

density of the product. • Nozzle adjustable twisting, manual casing hold. • Clear visual

indication of remaining product. • Counters for batch/total number and weight.

FILLING MECHANICS: • 3 working modes: straight fill, portion and twist. • Single or

continuous operation, programable number of portions for automatic stop. • Portions from 5 g

up to 25 kg, very precise: only ± 1 g • Very fast, can produce up to hundreds of portions per

minute. • Number of nozzle twist adjustable from 1-15 revs. • Programable fill break.

S/S FRAME: • Very robust construction. • Completely stainless: entire frame, external and

internal, in AISI304 stainless steel, as well as all possible hardware and components.

• Polished surfaces without corners, with CE radius to facilitate cleaning and comply with

hygiene standards. • Double sealed waterproof access panels. • Closed machine bottom.

• Adjustable, stainless steel machine feet, non-slip and vibration absorbing.

HYDRAULICS, ELECTRICS AND ELECTRONICS: • Powerful motor, high hydraulic pressure, for the

densest or coldest products. • Temperature-controlled oil-cooling system • Easy access to electric

panel. • Hydraulic/electric components of first brands Hydac Germany and Schneider Electric. • Very

reliable and precise electronic internal digital communications using advanced new I/O Link industry

standard components Balluf Germany brand.

SOFTWARE AND EXTERNAL CONNECTIONS: • Control panel with large 15” Schneider Electric digital touch screen, all information

displayed simultaneously and in large size. Extensive information on controls, alarms, errors, diagnostics. • Very advanced and

practical software with numerous options. Intuitive, easy to use. • Interactive recipes, can be stored and executed directly on the

machine's screen. • Industry 4.0 digital solutions for maintenance, process integration and custom solutions. • Remote Service and

Support access over secure internet connection (ethernet cable or mobile phone).

STANDARD DELIVERED WITH: 5 nozzles ext Ø 14, 20, 30, 38 and 43 mm. • Hydraulic oil • S/s piston extraction wrench.